volatile corrosion inhibitors

Volatile Corrosion Inhibitors

Contact UsOverview

What are VCIs?

Volatile Corrosion Inhibitors (VCIs) are chemical compounds that release protective vapors to prevent metal surfaces from rust and corrosion, ensuring long-term durability and safety in storage and transportation.

VCIs are easy to use and highly effective across various metals and environments, making them ideal for industrial, marine, and manufacturing applications. They provide a cost-efficient solution to protect valuable equipment, machinery, and components from corrosion without the need for extensive maintenance.

VCI Applications:

-

Oil-Based System: Provides long-lasting corrosion protection for metals in storage and transit.

-

Non-Oil-Based System: A clean, residue-free option for corrosion prevention in sensitive environments.

-

Outdoor: Protects metals exposed to harsh weather and outdoor conditions.

-

Painting Preservation: Prevents corrosion under coatings and painted surfaces, ensuring long-term finish quality.

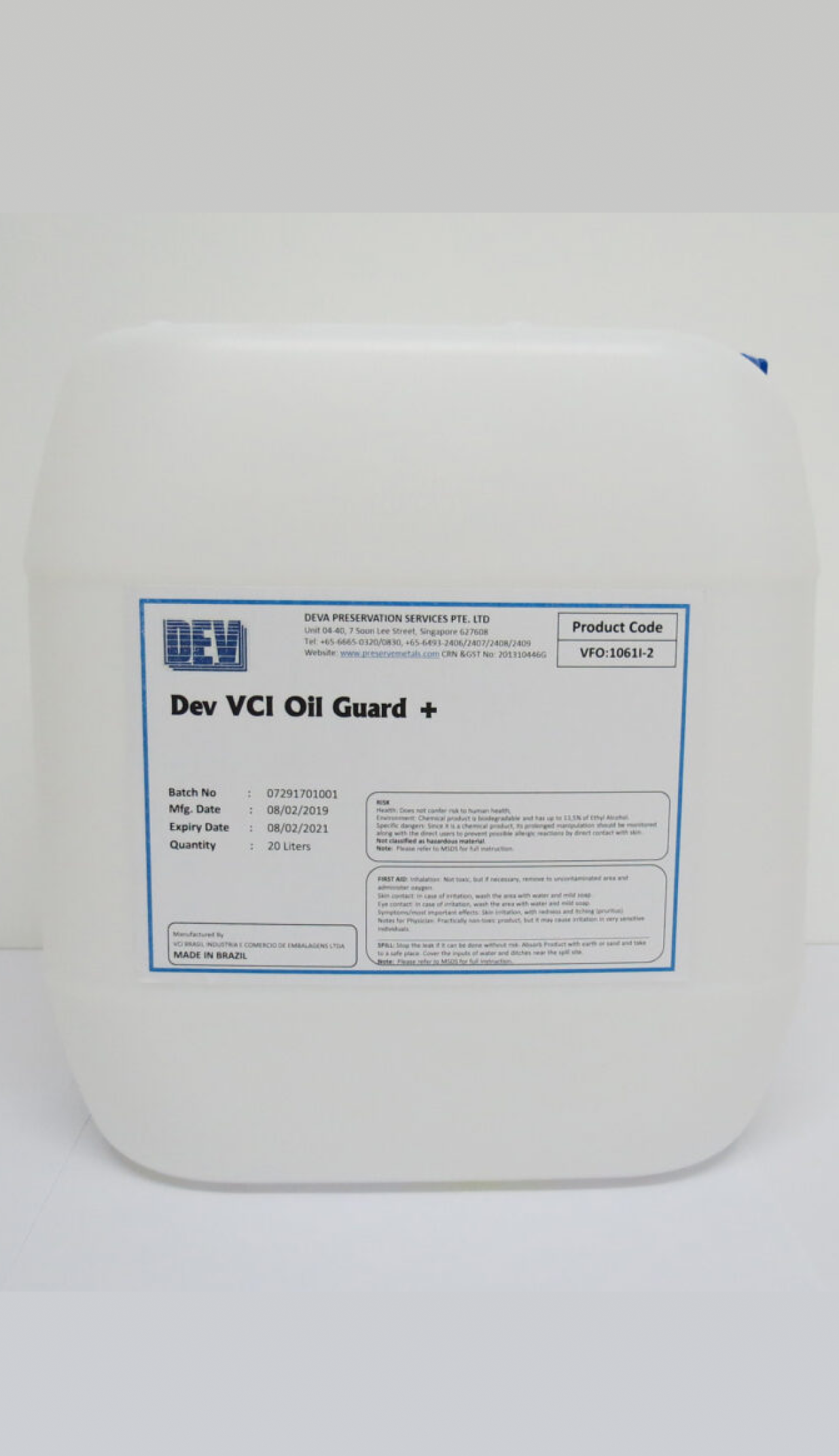

VCI oil based system

Overview

Oil-based, anti-corrosive additive that forms a protective film on the metal surface which is the empty space between the oil and the tank.

Application

This product is recommended for:

- Applying in closed environments where the air-phase anti-corrosive maintains itself staunch.

Properties

- High chemical stability.

- Forms an almost unnoticeable thin protective film able to affix stabilizing auto-repairable anti-corrosive surface.

Features & Benefits

- A biodegradable product which forms an almost undetectable thin film.

- Compatible with rubber, ferrous and non-ferrous materials.

Directions for Use

Spray Dev VCI O-Shield 92 to the bare metal surfaces to cover entire surfaces at the rate of 1 Lit./m³ or brush to the bare metal surfaces at the rate of 1 Lit./8m².

Storage & Packaging

- Available in 20L carboy can & 50L barrels.

- Do not reuse empty containers.

Overview

It is an innovative organic compound with differentiated molecular structure, safe for people and the environment, which remains active in the substrate where it is applied: diesel fuel, among others.

In the presence of metals, the Advanced VCI acts effectively in the vapor phase and by contact, interfering with the electrical activity, which gives stability to the metal surface. Free of Nitrite salts and heavy metals.

Applications

- Oils in general such as lubricating oil, transmission oil, hydraulic oil among others.

- Concentration of use: 2% of the content volume.

Properties

- Capacity to set/fix crystal stabilizers forming the anticorrosive surface: Advanced VCI.

- Excellent corrosion inhibiting property in both contact phase and vapor phase.

- Soluble in oil base and miscible in most of formulated oils in the market.

Features & Benefits

- Protects surfaces — both immersed and aerated surfaces.

- Oil soluble & miscible base in majority of formulated oils in the market.

Directions for Use

- Add 2% by volume of content.

- Dev VCI Oil Guard + is used as an additive.

Storage & Packaging

- Store away from heat, flame or sparks.

- Available in 20L jerry can & 200L barrels.

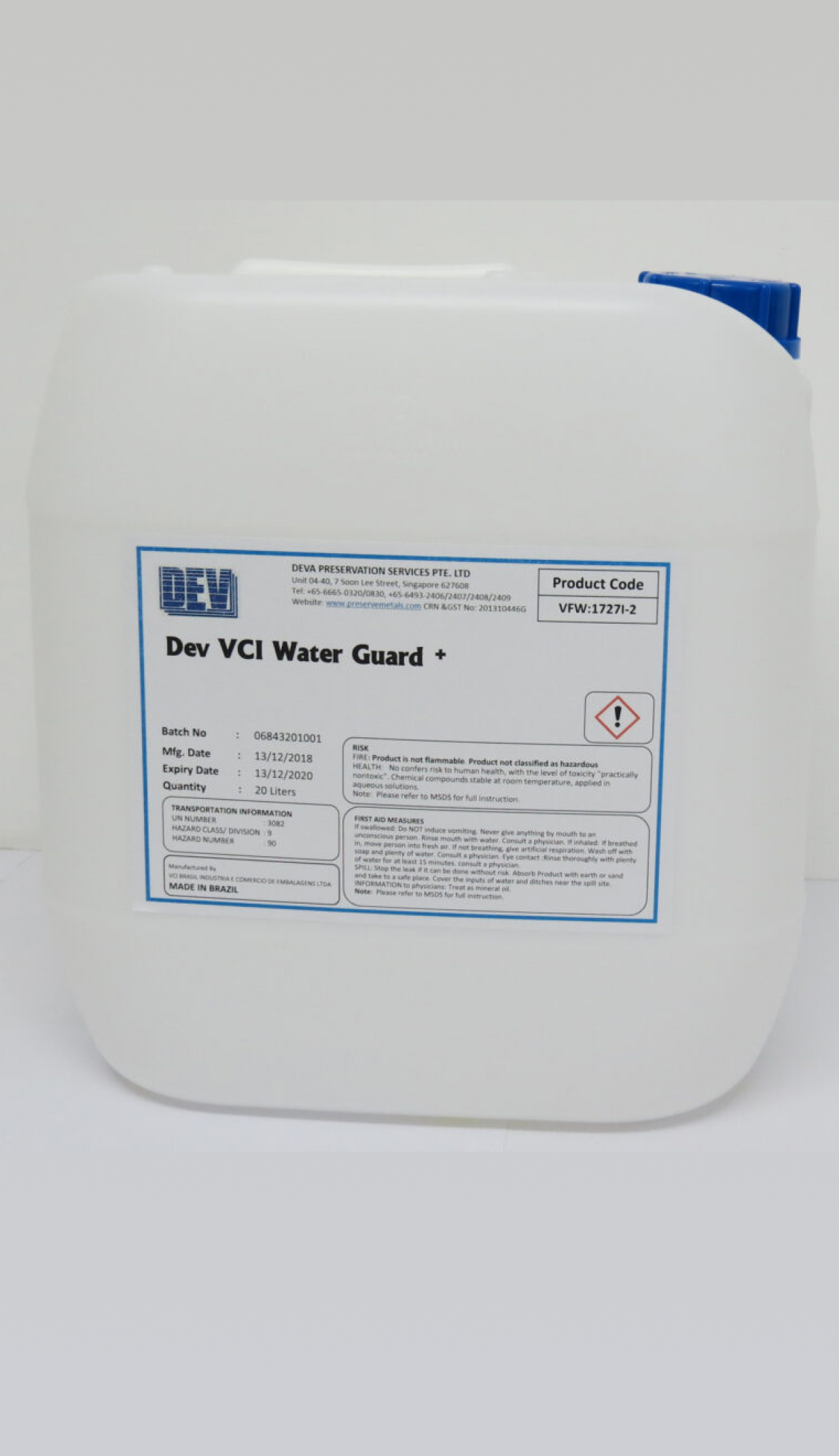

VCI non-oil based system

Overview

Additive for Water-based fluids suitable for fresh water circuits like cooling circuits, BOP fluids, hydraulic circuits for anti-corrosiveness for ferrous and non-ferrous metals.

Application

This product is recommended for:

- Internal protection.

- Hydrostatic tests where liquid need to be retained after tests.

Properties

- It is an easy to use, high performance product. Biodegradable.

- Forms an almost unnoticeable thin protective film able to affix stabilizing auto-repairable anti-corrosive surface.

Features & Benefits

- Dev VCI Water Guard+ can be used and retained inside the equipment to be preserved.

- Compatible with rubber, ferrous and non-ferrous materials, protect both immersed and aerated surfaces.

Directions for Use

Dev VCI Water Guard+ is used as an additive, 100% concentrated.

It is added as 2% of the volume of content.

Storage & Packaging

- Protects from harsh weather.

- Do not reuse empty containers.

- Available in 20L carboy can or 200L barrels.

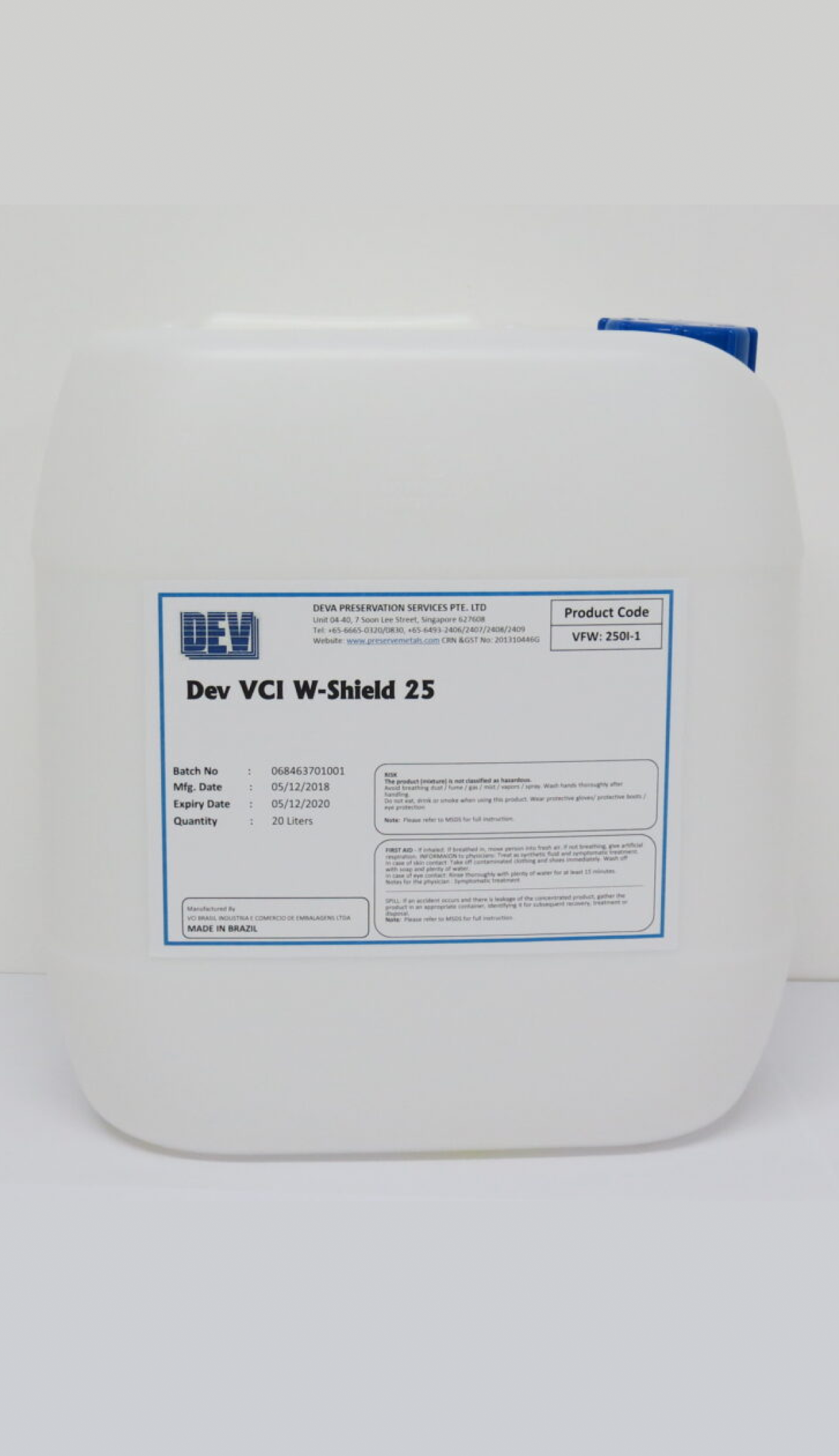

Overview

Water-based anti-corrosive product, comprised of organic raw materials that avoid the need for solid, greasy residues to form a protective film on treated surfaces. Excellent preservative for water-based empty system, pipelines, as well as filled in system.

Applications

- Internal and external protection of wrapped ferrous and non-ferrous parts and equipment stored indoors.

- It is also used in hydrostatic tests.

Properties

- It is an easy to apply, high performance product.

- Forms an almost unnoticeable thin protective film able to affix stabilizing auto-repairable anti-corrosive surface.

- Biodegradable

Features & Benefits

- Dev VCI W-Shield 25 is very effective in preservation of tanks, internals of pipes, etc.

- Compatible with rubber, ferrous and non-ferrous materials.

Directions for Use

- Dev VCI W-Shield 25 can be applied spray, brush, rolling or can be directly added in water-based fluids at the time of stagnation like hydro testing, pressure testing, leak testing, etc.

- Additive: 2% of the content volume.

- Spraying: 20-30% solution at the rate of 1L/m3 of volume.

- Brushing: 30% solution at the rate of 1L/8m2 of surface area directly apply on the walls of tanks, where the brush can be reached.

Storage & Packaging

- Do not reuse empty containers.

- Available in 20L carboy can or 200L barrels.

VCI outdoor Only

Overview

- It is a heat shrinkable polymer film used for metallic materials packaging.

- Protection against corrosion of ferrous and non-ferrous materials during storage and shipment.

Application

This product is recommended for:

- Internal protection.

- Hydrostatic tests where liquid needs to be retained after tests.

Properties

- VCI CONTENT: Active VCI compound applied at 2–3% on PE resin, co-extruded in various thicknesses.

- Non-toxic, biodegradable, free from nitrites, nitrates, chromates, sulfates & heavy metals.

- THICKNESS: 200 microns.

Features & Benefits

- VCI in the plastic is practically non-toxic and totally biodegradable.

- Recyclable with anti-UV packaging, dissipates vapour over long periods (2–3 years protection).

- Anti-flame retardant, classified under UL94; UV-resistant up to index 9–10 for over 3 years.

- Maintains effectiveness for 2+ years after exposure.

Directions for Use

- Wrap film completely around metal item to be protected.

- Ensure previously applied preservatives are dried.

- Heat the plastic to shrink tightly and seal joints air-tight.

- Use cloth pads on sharp edges for better shrink and reduced damage.

Storage & Packaging

- Store away from heat, flame, or sparks.

- Available in 200 microns thickness, 6m width (folded to 2m), 50kg rolls.

- Shelf life: 24 months in original packaging.

Overview

Suitable for stretch metal / material packaging. Protection against corrosion of ferrous and non-ferrous metal material in the storage and shipment processes.

Applications

- Internal and external protection of wrapped ferrous and non-ferrous parts and equipment stored indoors.

- It is also used in hydrostatic tests.

Properties

- VCI CONTENT: Active VCI compound applied at 2 – 3% on PEBD resin. It can be co-extruded in different thicknesses and PE resin mixtures.

- Non-toxic VCI “Volatile Corrosion Inhibitor” TOXICITY level as low as: LD50 orally > 2000 mg/kg. Material completely free of nitrites nitrates, chromates, sulfates and heavy metals.

- THICKNESS: 25 ~ 80 microns

Features & Benefits

- Practically recyclable product, totally biodegradable and recyclable Anti-UV packaging.

- This product is derived from non-aromatic amines which are not included in the list of carcinogen amines.

- Anti-flame retardant, classified according to UL94.

- Product composed of 100% resin mixtures of Low Density Linear Polyethylene resins, without the addition of other chemical.

- Products which promote their adhesiveness. Thicknesses, with stretching, adhesive and transparency properties are at the best. Can be ordered as required.

Directions for use

- Film should be wrapped completely around the material/item to be protected against corrosion. If need overlap to avoid gaps.

- Make sure all previously applied preservative coating is dried, cover 100% of the bare metal.

- Stretch at the required level to the required shape tightly.

Storage & Packaging

- Store away from heat, flame or sparks.

- Available in 25, 60 and 80 microns thick, 0.5 /1.2 meters width in 3 kg rolls.

- Plastic film available in clear film, or which can be co-extruded into different colour as required.

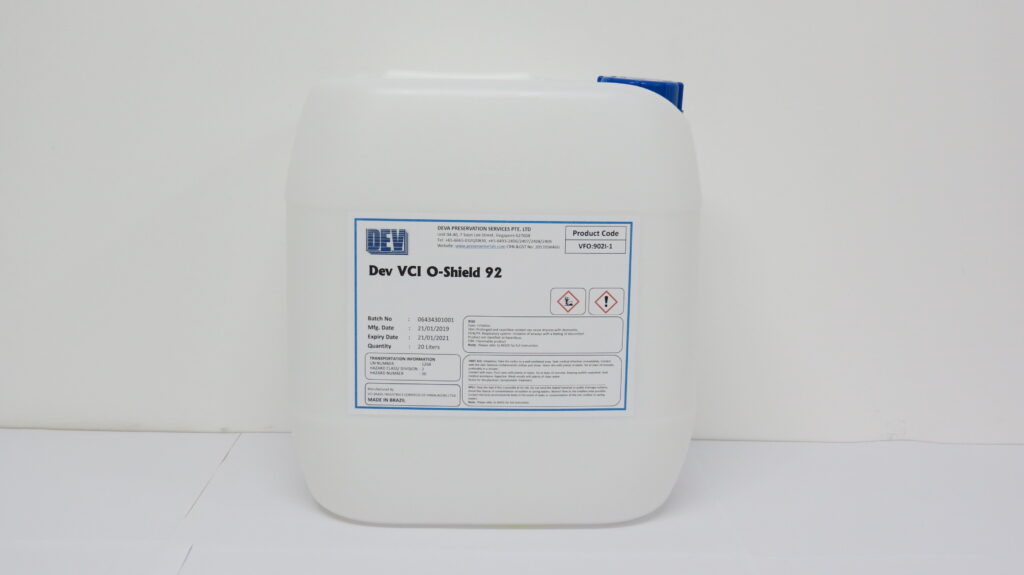

VCI oil based system

Overview

Oil-based, anti-corrosive additive that forms a protective film on the metal surface which is the empty space between the oil and the tank.

Application

This product is recommended for:

- Applying in closed environments where the air-phase anti-corrosive maintains itself staunch.

Properties

- High chemical stability.

- Forms an almost unnoticeable thin protective film able to affix stabilizing auto-repairable anti-corrosive surface.

Features & Benefits

- A biodegradable product which forms an almost undetectable thin film.

- Compatible with rubber, ferrous and non-ferrous materials.

Directions for use

Spray Dev VCI O-Shield 92 to the Bare Metal surfaces to cover entire surfaces at the rate of 1 Lit./m3 or Brush to the Bare Metal surfaces to cover entire surfaces at the rate of 1 Lit./8m2

Storage & Packaging

- Available in 20L carboy can & 50L barrels

- Do not reuse empty containers.

Overview

It is an innovative organic compound with differentiated molecular structure, safe for people and the environment, which remains active in the substrate where it is applied: diesel fuel, among others.

In the presence of metals, the Advanced VCI acts effectively in the vapor phase and by contact, interfering with the electrical activity, which gives stability to the metal surface. For fuel contaminated with water, which have a corrosive aggressiveness. Free of Nitrite salts and heavy metals.

Applications

- This product is recommended for: Oils in general such as lubricating oil, transmission oil, hydraulic oil among others.

- Concentration of use: 2% of the content volume.

Properties

- Capacity to set/fix crystal stabilizers forming the anticorrosive surface: Advanced VCI.

- Excellent corrosion inhibiting property in both contact phase and vapor phase.

- Soluble in oil base and miscible in most of formulated oils in the market.

Features & Benefits

- Protects surfaces-both immersed and aerated surfaces.

- Oil soluble & miscible base in majority of formulated oils in the market.

Directions for use

- Add 2% by volume of content.

- Dev VCI Oil Guard + is used as an additive.

Storage & Packaging

- Store away from heat, flame or sparks.

- Available in 20L jerry can & 200L barrels.

VCI non-oil based system

Overview

Additive for Water-based fluids suitable for fresh water circuits like cooling circuits, BOP fluids, hydraulic circuits for anti-corrosiveness for ferrous and non-ferrous metals.

Application

This product is recommended for:

- Internal protection.

- Hydrostatic tests where liquid need to be retained after tests.

Properties

- It is an easy to use, high performance product. Biodegradable.

- Forms an almost unnoticeable thin protective film able to affix stabilizing auto-repairable anti-corrosive surface.

Features & Benefits

- Dev VCI Water Guard+ can be used and retained inside the equipment to be preserved.

- Compatible with rubber, ferrous and non-ferrous materials, protect both immersed and aerated surfaces.

Direction of use

- Dev VCI Water Guard+ is used as an additive, 100% concentrated.

- It is added as 2% of the volume of content.

Storage & Packaging

- Protects from harsh weather.

- Do not reuse empty containers.

- Available in 20L carboy can or 200L barrels.

Overview

Water-based anti-corrosive product, comprised of organic raw materials that avoid the need for solid, greasy residues to form a protective film on treated surfaces. Excellent preservative for water-based empty system, pipelines, as well as filled in system.

Applications

- Internal and external protection of wrapped ferrous and non-ferrous parts and equipment stored indoors.

- It is also used in hydrostatic tests.

Properties

- It is an easy to apply, high performance product.

- Forms an almost unnoticeable thin protective film able to affix stabilizing auto-repairable anti-corrosive surface.

- Biodegradable

Features & Benefits

- Dev VCI W-Shield 25 is very effective in preservation of tanks, internals of pipes, etc.

- Compatible with rubber, ferrous and non-ferrous materials.

Directions for use

- Dev VCI W-Shield 25 can be applied spray, brush, rolling or can be directly added in water-based fluids at the time of stagnation like hydro testing, pressure testing, leak testing,etc.

- Additive: 2% of the content volume.

- Spraying: 20-30% solution at the rate of 1L/m3 of volume.

- Brushing: 30% solution at the rate of 1L/8m2 of surface area directly apply on the walls of tanks, where the brush can be reached.

Storage & Packaging

- Do not reuse empty containers.

- Available in 20L carboy can or 200L barrels.

VCI outdoor Only

Direction of use

- Film should be wrapped completely around the material/item to be protected against corrosion.

- Make sure all previously applied preservatives have dried. Cover 100% of the bare metal.

- Heat the plastic at the required area to shrink to the required shape tightly. Gently touch with clean cloth pads & seal the joints for air-tight sealing. Add pads on sharper edges for better shrink and less damages.

Storage & Packaging

- Store away from heat, flame or sparks.

- Available in 200 microns thick, 6 meters width folded to 2 Meter width as roll in 50 kg rolls.

- Shelf life of the VCI in original package is 24 months.

Overview

- It is a heat shrinkable polymer film used for metallic materials packaging

- Protection against corrosion of ferrous and non-ferrous material in the storage and/or shipment processes.

Application

This product is recommended for:

- Internal protection.

- Hydrostatic tests where liquid need to be retained after tests.

Properties

- VCI CONTENT: Active VCI compound applied at 2 – 3% on PE resin. It can be co-extruded in different thicknesses and PE resin mixtures.

- Made out of non-toxic VCI “Volatile Corrosion Inhibitor”. Toxicity is as low as LD50 orally > 2000 mg/kg.

- Material completely free of nitrites, nitrates, chromates, sulfates and heavy metals.

- THICKNESS: 200 microns.

Features & Benefits

- VCI in the plastic is practically non-toxic product, totally biodegradable and the plastic is recyclable with Anti-UV packaging. Dissipates VCI vapour over long period of time. Suitable for protecting metal wrapped two to three years in good wrapped condition. VCI starts decay only after we open the package, otherwise it is in PE, no degradation in the original packed condition.

- Anti-flame retardant, classified according to UL94. This property only degrades when it starts exposed to sun’s UV. Added with UV filter in the molten plastic compound suitable for withstanding sun UV index as high as 9~10 level, over 3 years. We can assure excellent working, may be for over 2 years’ post exposure in the sun.

Directions for use

- Film should be wrapped completely around the material/item to be protected against corrosion. If need overlap to avoid gaps.

- Make sure all previously applied preservative coating is dried, cover 100% of the bare metal.

- Stretch at the required level to the required shape tightly.

Storage & Packaging

- Store away from heat, flame or sparks.

- Available in 25, 60 and 80 microns thick, 0.5 /1.2 meters width in 3 kg rolls.

- Plastic film available in clear film, or which can be co-extruded into different colour as required.

Overview

Suitable for stretch metal / material packaging. Protection against corrosion of ferrous and non-ferrous metal material in the storage and shipment processes.

Applications

- Internal and external protection of wrapped ferrous and non-ferrous parts and equipment stored indoors.

- It is also used in hydrostatic tests.

Properties

- VCI CONTENT: Active VCI compound applied at 2 – 3% on PEBD resin. It can be co-extruded in different thicknesses and PE resin mixtures.

- Non-toxic VCI “Volatile Corrosion Inhibitor” TOXICITY level as low as: LD50 orally > 2000 mg/kg. Material completely free of nitrites nitrates, chromates, sulfates and heavy metals.

- THICKNESS: 25 ~ 80 microns

Features & Benefits

- Practically recyclable product, totally biodegradable and recyclable Anti-UV packaging.

- This product is derived from non-aromatic amines which are not included in the list of carcinogen amines.

- Anti-flame retardant, classified according to UL94.

- Product composed of 100% resin mixtures of Low Density Linear Polyethylene resins, without the addition of other chemical.

- Products which promote their adhesiveness. Thicknesses, with stretching, adhesive and transparency properties are at the best. Can be ordered as required.

Anti-Corrosive Paints

Overview

DEV PU PRIMER is a single component moisture cure polyurea primer, combining Zinc and Micaceous Iron Oxide (MIO) into our proprietary blend moisture cured resin. This primer is designed for outstanding protection of steel from corrosion in high humidity climates, service under immersion, splash zone and areas with permanent condensation. The properties of the resin, high quality zinc and lamellar MIO, makes DEV PU PRIMER the perfect primer that provides both barrier and galvanic protection simultaneously.

Mixing

Material temperature must be 5 °F (3 °C) above the dew point before opening and agitating. Power mix thoroughly prior to application. Do not keep under constant agitation. Apply a 3-6 oz (9-18 cl) solvent float over material to prevent moisture intrusion and cover pail.

Surface preparation

For minimum surface preparation, use conscientious hand and power tool cleaning methods in accordance with ISO 8504-3 or SSPC-SP2 and 3 to remove corrosion and loose or failing paint to ISO 8501-1 St2 or SSPC-SP2 and 3 (visual standard SSPC vis 3). Feather-edges of sound, existing paint back to a firm edge.

Clean up

PU-Thinner, PU-Thinner 25 and PU-Thinner 50. If PU- Coatings thinners are not available, use MEK, MIBK, Xylene, a 50:50 blend of Xylene and MEK or MIBK, or acetone for clean up only. Do not add unauthorized solvents to a coating of PU-Coatings.

Application

DEV PU PRIMER can be applied by brush, roll, airless spray and conventional spray methods (one grade only). Follow proper mixing instructions before applying.

- Relative Humidity: 6% to 99%* PU-Quickcure is advised when relatives humidity’s are below 40%.

- Temperature: -20 °C to 75 °C (-4 °F to 167 °F) This temperature range should be achieved for ambient, surface and material temperature. Substrate must be visibly dry.

- Coating Accelerator: PU-Quickcure. See PU-Quickcure Product Data for information.

Storage

Store off the ground in a dry, protected area in temperature between 4 ºC to 30 °C (40 ºF to 86 °F). Containers must be kept sealed when not in use. Use a solvent float to reseal partial containers.

Storage

Store off the ground in a dry, protected area in temperature between 4 ºC to 30 °C (40 ºF to 86 °F). Containers must be kept sealed when not in use. Use a solvent float to reseal partial containers.

Clean up

Material temperature must be 5 °F (3 °C) above the dew point before opening and agitating. Power mix thoroughly prior to application. Do not keep under constant agitation. Apply a 3-6 oz (9-18 cl) solvent float over material to prevent moisture intrusion and cover pail.

Overview

Dev Pu Coat is a single component moisture curing intermediate coating, containing MIO and it is also a (non-UV) topcoat for new construction and maintenance projects.

Dev Pu Coat has proven outstanding barrier performance when used for immersion, splash zone or atmospheric exposure service. Dev Pu Coat is available in a light colour to facilitate interior tank inspection. Dev Pu Coat is also a primer for non-ferro.

It is ideal for use as a tie coat over most existing coatings and can be used in red lead encapsulation systems. Dev Pu Coat is also a standard primer for concrete.

Applications

Dev Pu Coat can be applied by brush, roll, airless spray and conventional spray methods (one grade only). Follow proper mixing instructions before applying.

- Relative Humidity: 6% to 99%* PU-Quickcure is advised when relatives humidity’s are below 40%.

- Temperature: -20 °C to 75 °C (-4 °F to 167 °F) This temperature range should be achieved for ambient, surface and material temperature. Substrate must be visibly dry.

- Coating Accelerator: MCU-Quickcure.See MCU-Quickcure Product Data for information

Overview

Special property blended thinner for the de MCU-Coatings paints.

Application

This product is for industrial use only.

WARNING: Vapour and spray mist is harmful. Use an approved respirator when applying this product. Protect skin and eyes from contact. Consult the material safety data sheet for further recommendations.

Properties

Apply a 3-6 oz (9-18cl) solvent float over material to prevent moisture intrusion and cover pail. Reduction is typically not required. Do not add unauthorized solvents to a MCU-Coatings´ paints.

Ready to experience our products?

Get in touch today to discuss your needs or explore our solutions.

Ready to experience our products?

Get in touch today to discuss your needs or explore our solutions.